- How Manufacturing Helps American Society in 2025: Jobs, Innovation, Security, Community Sep 11, 2025

- Top Manufacturing Businesses: Automotive and Electronics Industry Insights Jul 21, 2025

- The 5 Essential Stages of Food Processing Explained Oct 12, 2025

- Who Is the World’s Manufacturing Capital? A 2025 Deep Dive Oct 22, 2025

- What is the richest furniture company in the world? Nov 21, 2025

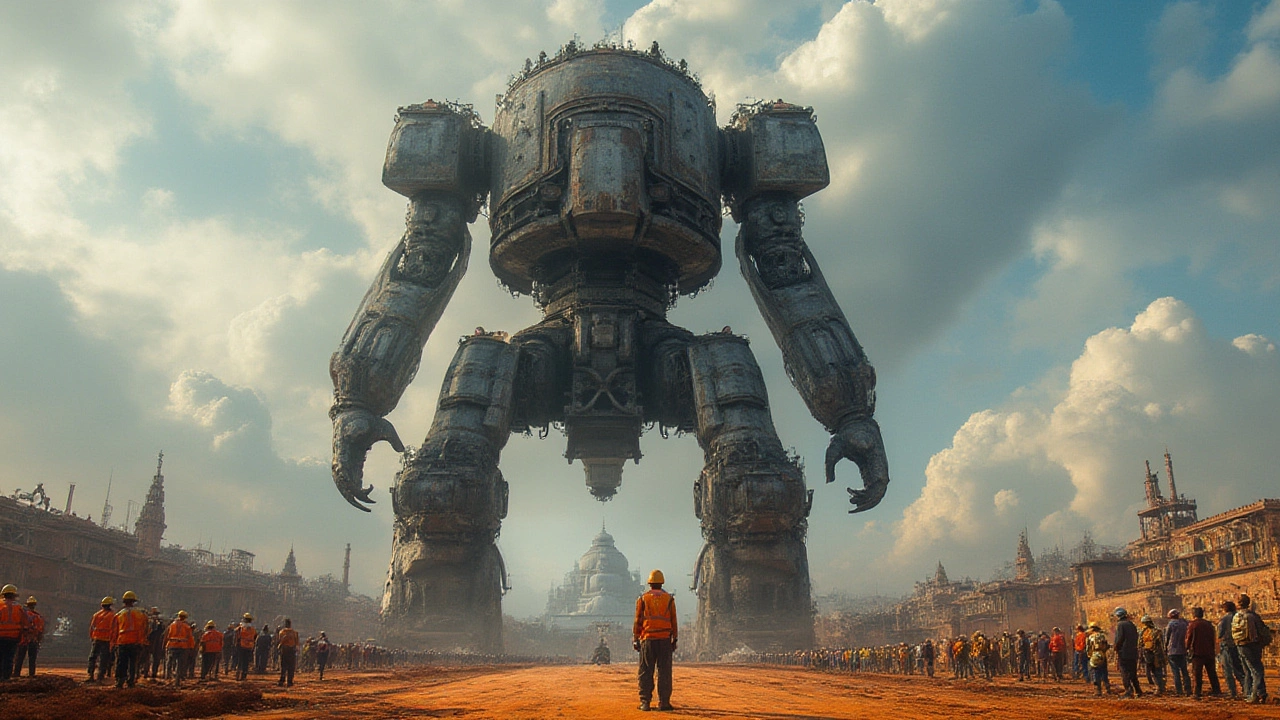

Largest Machinery: What They Are and Why They Matter

If you walk into any big factory, the first thing you notice is the sheer size of the equipment. Those giant presses, towering cranes, and massive furnaces aren’t just for show – they drive the whole production line. Knowing which machines are truly the largest helps you understand cost, space needs, and the kind of output you can expect.

Why Size Matters in Industrial Gear

Bigger machines usually mean higher capacity. A 10‑ton press can shape steel plates that a 2‑ton press can’t even touch. That translates to faster turnaround, lower per‑unit cost, and the ability to take on larger orders. At the same time, size brings challenges: more power consumption, stricter safety rules, and a bigger footprint on the shop floor.

Most companies balance these trade‑offs by matching the machine size to the product demand. If you’re making custom automotive frames, a huge CNC mill makes sense. If you’re producing tiny electronic components, a compact high‑precision line is the smarter choice.

Top Categories of the Largest Machinery

1. Heavy‑Duty Presses and Stamping Machines

These beasts can bend, cut, and shape metal sheets that are several centimeters thick. In India, steel plants use presses over 500 tons to produce rails and structural beams. The larger the press, the thicker the material you can handle.

2. High‑Capacity Furnaces and Kilns

From steel melting furnaces to cement kilns, size directly affects how much raw material you can process at once. Modern electric arc furnaces in the US can melt over 50 tons of scrap steel in a single batch, cutting energy use per ton.

3. Giant CNC Machines & 5‑Axis Machining Centers

When aerospace or automotive companies need complex parts, they turn to massive CNC rigs that can handle workpieces over a meter long. These machines combine size with precision, letting you carve intricate shapes from a single block.

4. AI Chip Fabrication Lines

While a chip fab isn’t “big” in the traditional sense, the cleanroom facilities and lithography equipment occupy huge spaces. In India, new fabs are setting up 300‑meter‑long production lines to meet the surge in AI hardware demand.

5. Massive Conveyors and Automated Storage Systems

Think of the giant belt systems you see at ports or in e‑commerce warehouses. They move dozens of pallets per minute, keeping the flow steady without manual labor.

Choosing the right large machine starts with three simple steps: assess your production volume, calculate the space you have, and factor in power and maintenance costs. Talk to vendors about modular options – some manufacturers sell a core unit that you can expand later, saving you from over‑building at the start.

Keep an eye on trends, too. Energy‑efficient motors, smart sensors, and predictive maintenance software are turning even the biggest machines into data‑driven assets. That means less downtime and a clearer picture of when you’ll need to upgrade.

Bottom line: the largest machinery can boost your output dramatically, but only if you match it to your real needs. Start small, measure results, and scale up only when the numbers justify it. With the right approach, those massive machines become the backbone of a thriving, future‑ready operation.

India's Biggest Machine: Discover the Largest Heavy Machinery Ever Built in India

- Aarav Sekhar

- Jul 16, 2025

Explore the story of the biggest machine in India. Packed with surprising facts, this guide reveals its record-breaking size, uses, and the awe-inspiring effort behind its creation.