Key Takeaways

- The five stages are raw material handling, cleaning & sorting, preparation & transformation, cooking & preservation, and packaging & distribution.

- Each stage has specific equipment, safety checks, and quality‑control points.

- Understanding these steps helps manufacturers improve efficiency and keeps consumers safe.

- Simple analogies make the stages easy to grasp even if you’re not a food‑tech professional.

- Practical tips at the end let you apply the concepts to small‑scale kitchens or large factories.

Food processing is the series of operations that turn raw agricultural products into safe, tasty, and market‑ready foods. Whether you’re watching a factory line or chopping veggies at home, the same logical flow applies. In this guide we break down the food processing stages that every producer - from a boutique jam maker to a multinational snack giant - follows.

1. Raw Material Handling (Receiving & Storage)

Raw ingredients are the starting point of any food‑processing chain. Farmers deliver crops, livestock, or seafood to the plant, and the first job is to preserve their quality until they move downstream.

- Key activities: weigh‑in, temperature check, moisture measurement, and initial segregation (e.g., grade A vs. grade B).

- Typical equipment: insulated trucks, bulk silos, refrigerated warehouses, and conveyor belts with barcode scanners.

- Quality‑control tip: Perform a quick visual inspection and a sample lab test within the first 24hours to catch early spoilage.

Why does this matter? A single spoiled batch can cascade into wasted labor and costly recalls later on.

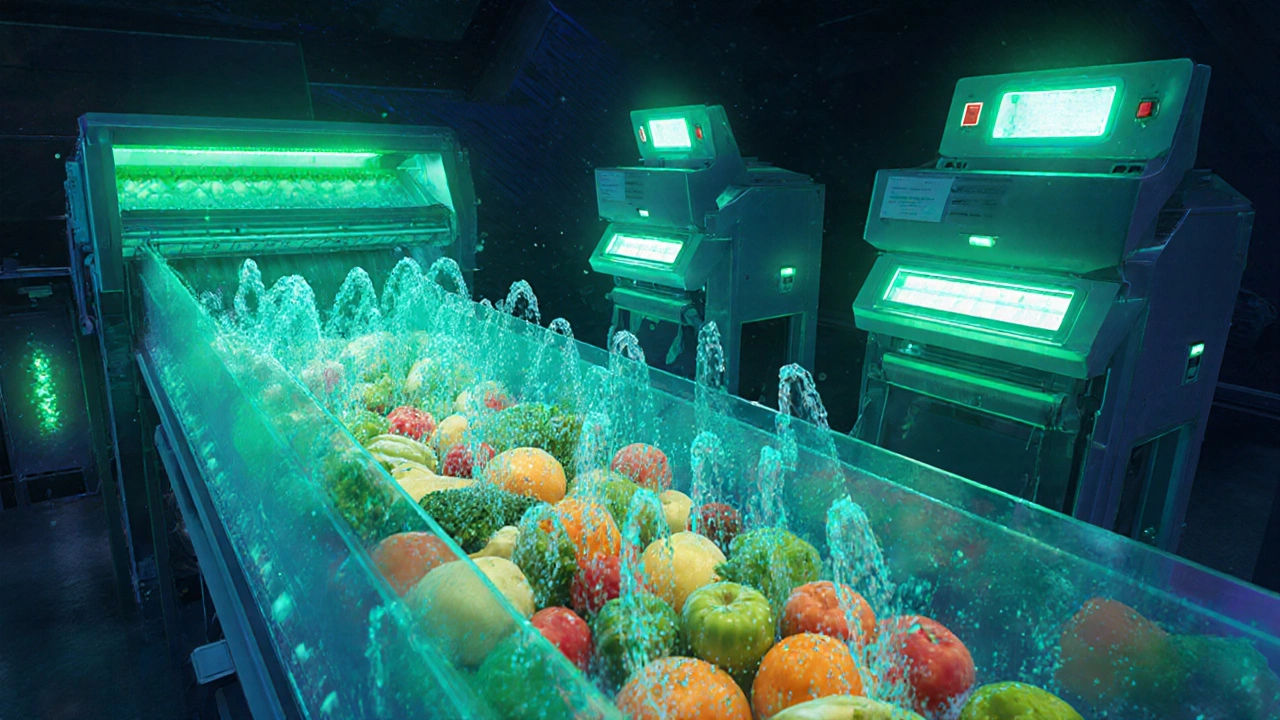

2. Cleaning & Sorting

Before any transformation, raw foods must be cleaned and sorted to remove dirt, pesticides, foreign objects, and off‑spec items.

- Washing methods: spray wash, ultrasonic baths, or counter‑current water streams, depending on the product’s fragility.

- Sorting technologies: optical sorters, magnetic separators, and X‑ray scanners that flag metal fragments or stones.

- Safety note: Follow HACCP (Hazard Analysis Critical Control Point) guidelines - the most critical control point for cleaning is usually the water quality check.

Effective cleaning reduces microbial load and improves yields in later stages.

3. Preparation & Transformation

This is where raw foods become recognizable ingredients. Preparation includes cutting, grinding, blanching, or mixing according to the recipe.

- Cutting & sizing: slicers, dicers, and spiralizers shape the product for uniform cooking.

- Mixing & forming: planetary mixers, extruders, and kneading machines create doughs, batters, or meat analogues.

- Pre‑treatments: blanching (brief boiling) inactivates enzymes in vegetables, extending shelf life.

Precision here matters - a 2mm deviation in slice thickness can change cooking time by 30%.

4. Cooking & Preservation

Heat is the most common preservation tool. Cooking includes baking, frying, steaming, or pasteurizing to develop flavor, texture, and safety.

- Baking: ovens with controlled humidity for bread, pastries, or ready‑to‑eat meals.

- Frying: continuous fryers that maintain oil temperature within ±2°C to avoid oil degradation.

- Pasteurization & sterilization: high‑temperature short‑time (HTST) systems for dairy or ultra‑high temperature (UHT) for shelf‑stable drinks.

Beyond heat, other preservation methods-such as freezing, drying, or fermentation-can be used. The key is to hit the critical control point identified in the HACCP plan (e.g., core temperature of 75°C for 30seconds for poultry).

5. Packaging & Distribution

The final stage locks in quality and prepares the product for the market. Packaging protects, informs, and markets the food.

- Primary packaging: vacuum‑sealed bags, PET bottles, or aluminum trays that directly contact the food.

- Secondary packaging: cardboard boxes, shrink‑wrap, or pallets for bulk handling.

- Labeling compliance: nutritional information, allergens, and best‑by dates must meet EU Food Information Regulation (EU1169/2011).

Distribution logistics-temperature‑controlled trucks, real‑time GPS tracking, and first‑in‑first‑out (FIFO) inventory-ensure the product reaches shelves while still safe.

Stage‑by‑Stage Quick Reference Table

| Stage | Main Activity | Typical Equipment | Key Quality Check |

|---|---|---|---|

| Raw Material Handling | Receiving, weighing, initial storage | Refrigerated silos, conveyor belts | Temperature & moisture test |

| Cleaning & Sorting | Washing, de‑contamination, defect removal | Spray washers, optical sorters | Water quality & foreign‑object detection |

| Preparation & Transformation | Cutting, mixing, pre‑treatments | Slicers, extruders, blenders | Size uniformity & enzyme inactivation |

| Cooking & Preservation | Heat treatment, drying, freezing | Ovens, fryers, HTST pasteurizers | Core temperature & shelf‑life testing |

| Packaging & Distribution | Sealing, labeling, logistics | Vacuum sealers, packaging lines, refrigerated trucks | Label compliance & temperature monitoring |

Practical Tips for Small‑Scale Producers

- Invest in a portable hand‑wash system with a built‑in sanitizer tank - it covers cleaning without a huge capital outlay.

- Use a digital thermometer with a data‑logger to capture every cooking run; this creates a quick HACCP record.

- Choose vacuum‑seal bags that fit your product size; they extend refrigerated shelf life by up to 40%.

- Label using a software template that auto‑fills nutrition facts based on ingredient databases - it saves hours of manual entry.

- Implement a simple FIFO spreadsheet; track batch numbers and expiry dates to avoid accidental sell‑through of older stock.

Common Pitfalls and How to Avoid Them

- Skipping the initial temperature check: Leads to hidden spoilage that only surfaces during cooking.

- Over‑relying on visual inspection: Microscopic pathogens won’t be seen; pair visual checks with rapid microbial tests.

- Inconsistent slice thickness: Causes uneven cooking and waste; calibrate slicers daily.

- Neglecting packaging integrity: Poor seals invite oxygen and moisture; perform a burst‑test on a sample batch each shift.

- Ignoring cold‑chain breaks during distribution: Use data loggers with alarm thresholds to catch temperature excursions early.

Next‑Level Resources

If you want to dig deeper, consider these reputable sources:

- EU Food Safety Authority (EFSA) reports - offer up‑to‑date risk assessments.

- Food Processing Handbook (3rded., 2023) - detailed equipment specs and design equations.

- Local university extension programs - often run short courses on HACCP implementation.

Frequently Asked Questions

What is the first stage of food processing?

The first stage is raw material handling, where ingredients are received, weighed, inspected, and stored under appropriate conditions.

Why is cleaning considered a separate stage?

Cleaning removes physical contaminants and reduces microbial load before any transformation, ensuring safety and preventing defects later in the line.

How does cooking affect shelf life?

Heat kills most spoilage microorganisms and inactivates enzymes, which dramatically extends shelf life. The exact gain depends on temperature, time, and the product’s intrinsic properties.

What packaging material gives the longest shelf life for dairy?

Aseptic cartons combined with UHT treatment typically provide the longest unrefrigerated shelf life (up to 6 months) for dairy beverages.

Can small producers skip HACCP?

Legally, any business that handles food for public sale must follow HACCP principles. Even a simple one‑page plan can satisfy inspectors and protect against recalls.