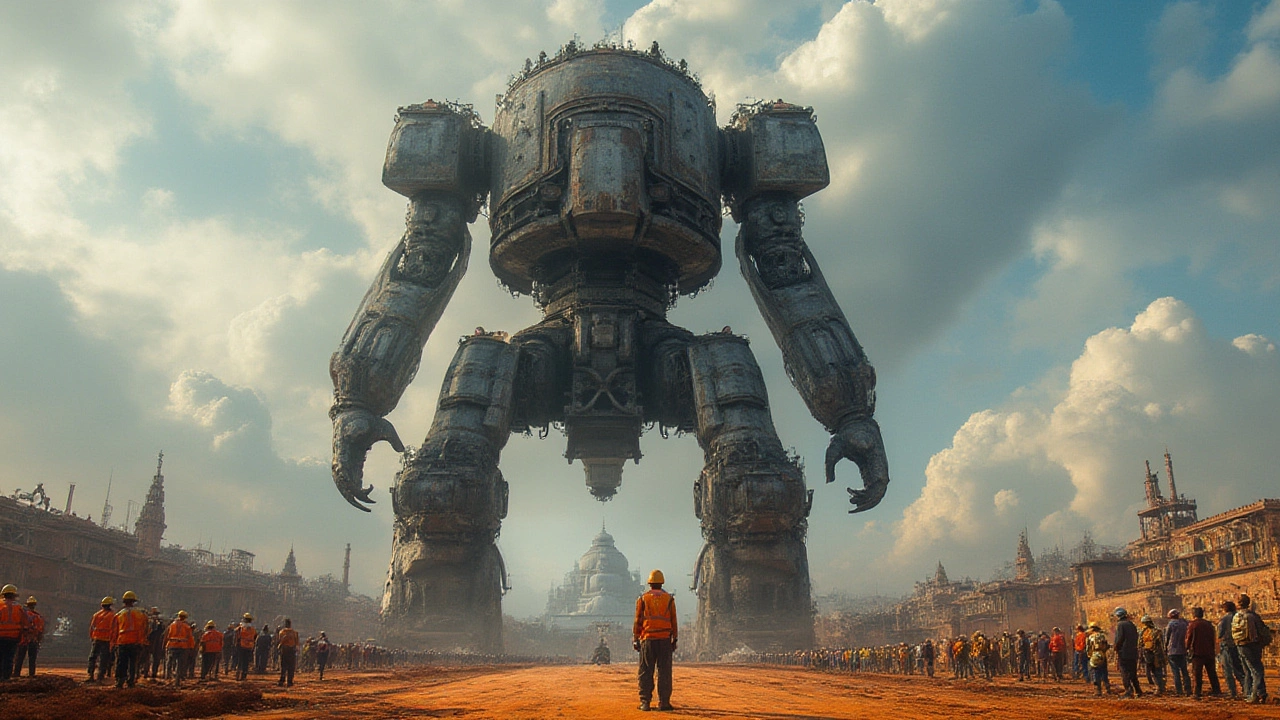

Ever wondered what the biggest machine in India actually is? It's not a spaceship, not a bullet train, and not even a massive cargo ship. It's something built right here, powered daily, and often hidden in plain sight. India has been home to some jaw-dropping heavy equipment and engineering feats—machines that dwarf trucks, cranes, and even most buildings. Forget what you think you know about machines; this isn't your average piece of machinery. Prepare for a story that’s as much about grit and genius as it is about metal and gears.

The Mammoth: Buckets Bigger Than Buses

When you think of enormous machines, your mind probably jumps to giant mining trucks or those construction cranes dotting the skyline. But none of them can compete in sheer mass and scale with the BEML BE1950—a bucket wheel excavator considered the biggest machine in India. Let’s put its size in perspective. This colossus is about 165 meters long and 12 stories high. Just one of its buckets can scoop up more earth than a city bus could ever carry—these buckets can hold over 1.5 cubic meters of material at a time.

This monster excavator finds its home in the coalfields of Northern Coalfields Limited (NCL), Singrauli, Madhya Pradesh. Mining runs nearly non-stop, and the BE1950 remains the backbone, chomping through tens of thousands of tons of overburden every day. If you stacked its buckets one atop another, you’d climb past a mid-sized apartment building. It runs on electric power from a separate substation, with more electricity flowing through it in a day than most entire neighborhoods use.

What makes it even cooler is the fact that it travels on its own tracks. Slowly, sure, but imagine a machine that weighs thousands of tons inching ahead, its giant wheel spinning, never flagging. The entire operation is coordinated by a small crew high up in air-conditioned glass cabins, keeping an eye on a panoramic view you usually only see in movies. It doesn’t just dig; it shapes the very face of the land, making the BE1950 both awesome and slightly intimidating.

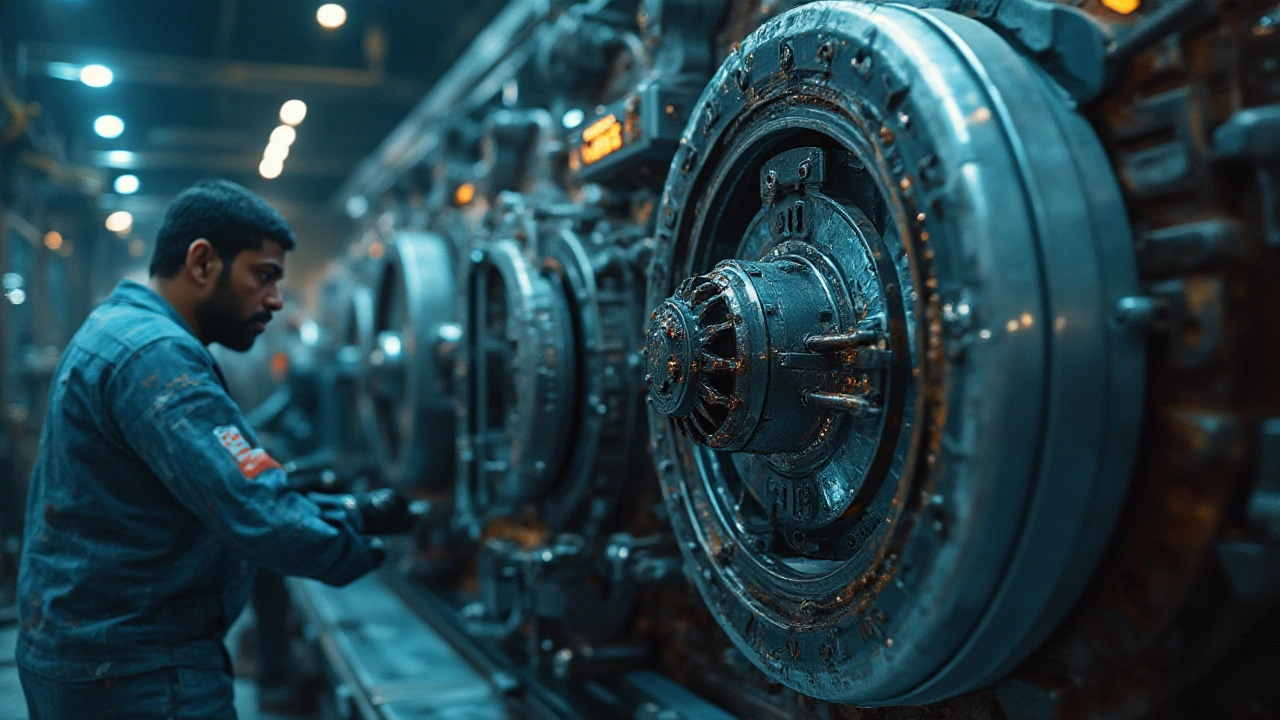

To keep this machine running takes coordination on a level most of us can’t imagine. Every part—from its 84 buckets to the 5-kilometer spread of its power cables—has to be monitored and maintained. Spare parts are ordered months in advance, and specialized engineers are flown in if something as much as a pivot bolt wears out. Think F1 pit crew, but for something that’s longer than a football field.

Just for comparison, here’s a table showing how the BE1950 stacks up against other huge machines often seen in India:

| Machine Name | Type | Length (meters) | Height (meters) | Bucket/Load Capacity |

|---|---|---|---|---|

| BEML BE1950 | Bucket Wheel Excavator | 165 | 35 | 1.5 m³ per bucket, 84 buckets |

| Tata Hitachi EX5600 | Hydraulic Excavator | 12.8 | 7.5 | 29 m³ (one bucket) |

| BEML BH205E | Dump Truck | 9.6 | 5.4 | 205 tons |

Anyone who visits the site, even seasoned workers, admits to feeling tiny next to this beast. It’s not just a machine; it’s almost a moving building.

The Giants Behind the Giant: Who Built It?

Machines like the BE1950 don’t come about because someone just wanted something big. Their creation is a story of India’s push for energy independence. Open-cast coal mining demands serious muscle—and in the 1980s, India wanted to rely less on imported heavy equipment. Bharat Earth Movers Limited (BEML), one of India’s largest public sector manufacturing companies, took the challenge. They partnered with leading German technology providers, blending foreign expertise with Indian engineering acumen. The result? The BE1950 and its fleet of bucket wheel excavators, now iconic symbols in India’s mining industry.

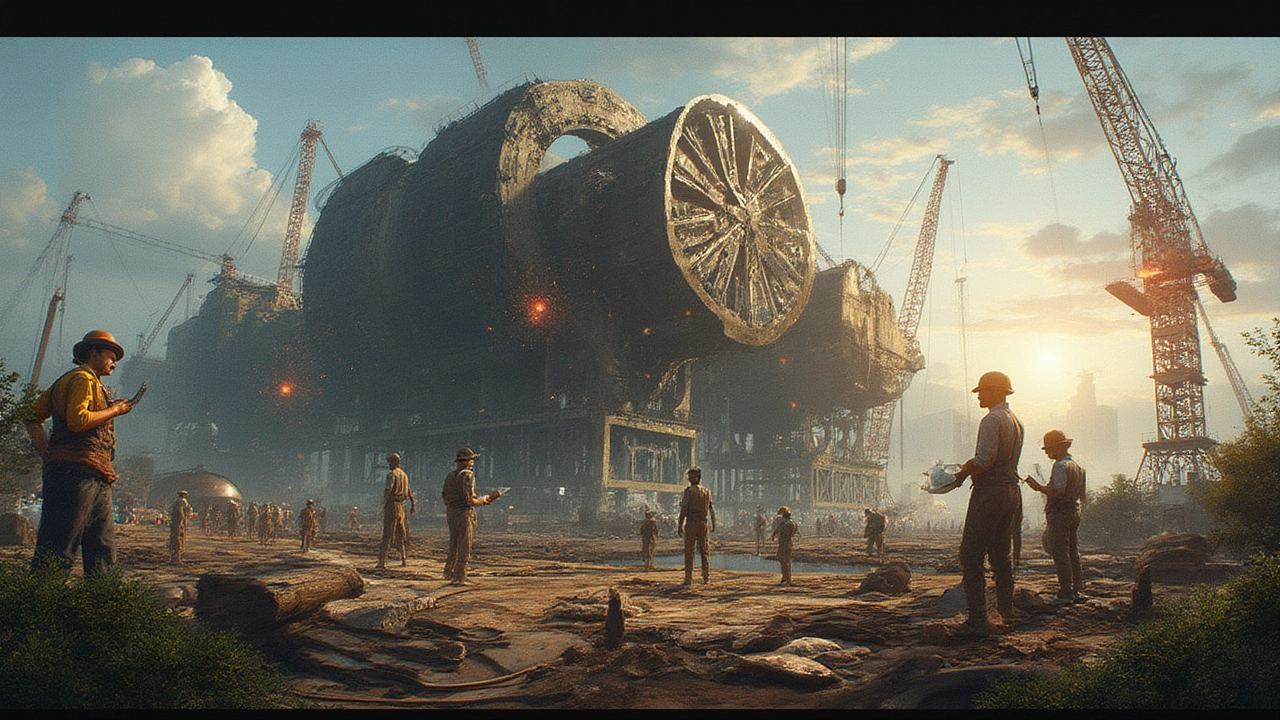

Building something this enormous meant solving challenges that wouldn’t even exist for smaller equipment. For one, every joint and connecting part had to survive insane heat, dust, and round-the-clock operations. The design team went through hundreds of blueprints, stress-tested materials, and had to even create new supply chains for parts that had never been made in India before. Bringing together Indian talent and imported know-how was no easy task—there were stories of engineers camping at sites for months just to supervise the most delicate assembly tasks.

Transport was its own beast. Imagine moving 165-meter-long pieces of machinery across remote regions with roads barely wide enough for trucks. Sometimes, bridges needed reinforcement or new pathways had to be cleared. Specialized convoys would crawl at walking pace, stopping traffic for hours while monstrous bolts, girders, and wheels rolled past. You’ll even hear about entire villages gathering to watch the machine’s final assembly—like a festival where everyone’s eyes were on this metallic monster taking shape.

BEML didn’t just stop at digging machines. The same company’s engineers also helped design giant dump trucks, rail coaches, and even metro trains that now run in cities like Bangalore and Delhi. But the BE1950 remains something people talk about with a mix of pride and disbelief. For BEML, cracking this nut meant putting India on the international map for heavy engineering. International mining companies started looking to India for solutions, not just raw labor.

There’s a lesson here, too. Big machines aren’t just about size—they’re about overcoming big problems. The BE1950 story reminds us that where there’s a mad vision, there are Indian engineers dreaming big enough to make it real.

Machines Changing India’s Landscape

Most people picture India’s machines as the cars built in Pune, the auto-rickshaws weaving through Mumbai, or the giant steel plants outside Jamshedpur. But dig a little deeper, literally, and the country’s largest machines are literally carving the land. They speed up mining, move mountains (sometimes literally), and build the highways and power stations that keep the country moving. Every year, the biggest machines get pushed further—taller cranes, stronger backhoes, and smarter robots keep joining the ranks.

India has seen a surge in demand for heavy machinery since the 2000s. Big infrastructure projects—metros, bridges, highways—need fast, reliable, and gigantic machines. Indian cities have been expanding at a crazy pace, and without these giants, those skylines simply wouldn’t exist. Even in agriculture, machinery like combine harvesters and large-scale tractors have changed how India grows and feeds more than a billion people.

Take the Sardar Sarovar Dam construction—a project where the country rolled out everything from India’s largest cranes to custom-built river diversions. Or look at the pipelines carrying water and gas for thousands of kilometers, laid by machines specifically designed for the terrain. In coal mining, the big bucket wheel excavators and dump trucks don’t just speed up processes; they have changed entire regions by making vast overburden removal possible.

The side effects? Bigger, smarter machines mean fewer hazards for workers and more work done in less time. Automated systems have been introduced to monitor wear-and-tear, and data is now crunched in real time so breakdowns cause minimal hiccup. With electric and hybrid heavy equipment now arriving, India is getting ready for a wave of quieter, cleaner giants on site.

But these machines are also stories of people. Every operator, mechanic, and engineer working with these giants learns a lesson in both humility and dedication. The best Indian heavy machine operators often have decades of experience. They know when a sound isn’t quite right or a vibration feels off—a skill as valuable as any engineering degree.

If you’re fascinated by these moving mountains, it’s worth following developments from companies like Larsen & Toubro, Tata Hitachi, and BEML, as they keep pushing the envelope, sometimes in partnership with international giants, sometimes on their own.

Tech Innovations: The Cutting Edge of Heavy Machinery

It’s not all about brute force anymore. The biggest machines in India are now getting brains. Picture the BE1950: originally controlled with levers and switches, but now, new generations of heavy equipment are getting digital dashboards, GPS tracking, and even “predictive failure” algorithms. Machines can self-diagnose, warning their operators before a breakdown even occurs.

Modern excavators and dumpers are now equipped with high-definition cameras, sensors measuring every angle, and connections to central computers that monitor everything from fuel burn to hydraulic pressure. One small tweak in the operations center can smooth out a week’s worth of productivity. There are now remote-controlled or even semi-autonomous machines in Indian mining—operators can sit comfortably in an office building, steering a giant excavator on a scorching plain miles away.

There’s also a green side starting to gain momentum. India’s largest earth movers and cranes are being designed for minimal emissions, and some machines run on hybrid engines that sip fuel. Even oil changes are tracked with sensors to reduce waste and prevent accidental spills. In the future, we might even see these mega-machines running entirely on solar or electric power, making them cleaner and quieter while still being jaw-droppingly huge.

Indian startups are getting in on the game too, designing robot welders and 3D-printed replacement parts that fit giant machines down to the bolt. Drone surveys now help plan every scoop that the biggest bucket wheel excavators take, reducing errors and costs. These tech leaps not only save money—they save lives and let humans focus on less risky, more skill-based tasks.

Of course, the dream machine isn’t just bigger; it's smarter, safer, and better for the environment.

How India’s Big Machines Stack Up Globally

India hasn’t yet built the world’s largest machine overall; that honor goes to some German and American mining behemoths (think Bagger 288 in Germany). But the BEML BE1950 is Asia’s largest bucket wheel excavator and among the top worldwide in terms of size and digging capacity. It places India right up there with countries that have a tradition of bold, giant construction. The BE1950 and similar machines put Indian manufacturing and engineering in the global spotlight—a testament that the country isn’t just a market for heavy machinery; it’s a creator, too.

Check out this data comparing bucket wheel excavators worldwide:

| Machine Name | Country | Length (meters) | Height (meters) | Operational Weight (tons) |

|---|---|---|---|---|

| Bagger 288 | Germany | 240 | 96 | 13,500 |

| BEML BE1950 | India | 165 | 35 | ~4,500 |

| MAN Takraf RB293 | Germany | 225 | 94.5 | 14,200 |

What’s exciting is not just the size, but the commitment to keep increasing local content and technical know-how with every project. Machines like the biggest machine in India are a stamp of Indian ingenuity, showing that those “Made in India” stickers now belong on some of the world’s most impressive engineering creations. They serve as case studies for students, inspire new generations of designers, and—let's not forget—give India’s infrastructure projects the muscle they need.

So next time you hear a distant rumble in the fields of Madhya Pradesh or see a convoy carrying some bizarrely oversized part on the highway, remember: you’re looking at the heart of India’s industrial ambitions, roaring and clanking its way into history.