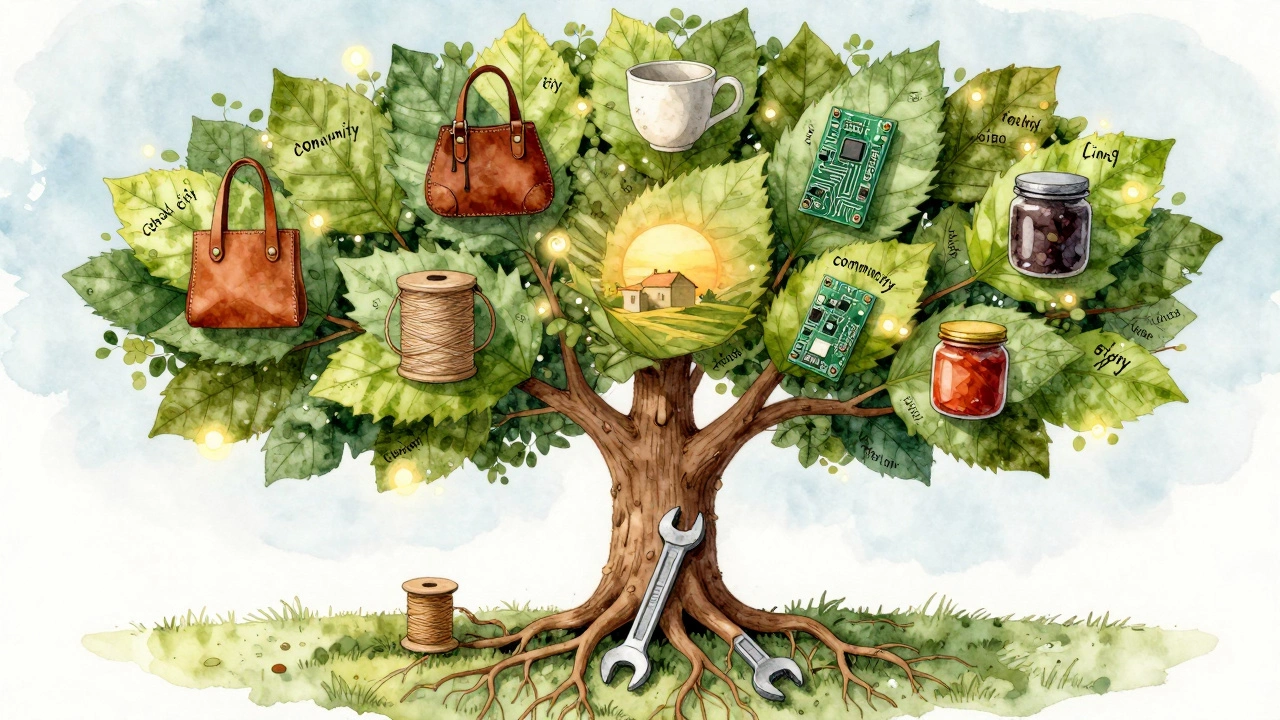

A small manufacturer isn’t just a tiny factory. It’s a business that makes physical products with limited resources, often in a single location, and usually with fewer than 100 employees. These companies don’t have corporate offices or global supply chains. They work out of garages, warehouses, or converted storefronts. They might make custom metal brackets, hand-sewn leather bags, organic jams, or printed circuit boards for local tech startups. What sets them apart isn’t size-it’s how they operate.

What Defines a Small Manufacturer?

The U.S. Small Business Administration (SBA) defines a small manufacturer as one with fewer than 500 employees. But in practice, most small manufacturers have fewer than 50. Some operate with just three people. They don’t need to meet a strict employee count to qualify-they need to be independent, locally rooted, and flexible.

These businesses typically:

- Produce goods in batches, not mass production lines

- Use manual or semi-automated equipment

- Source materials locally when possible

- Handle sales, shipping, and customer service themselves

- Adapt quickly to custom orders or changing demand

Think of them as the opposite of Amazon’s fulfillment centers. A small manufacturer might spend a week making 200 hand-painted ceramic mugs for a wedding vendor. Another might build 10 custom wooden bookshelves per month for a local interior designer. They don’t chase volume-they chase quality, relationships, and control.

Common Industries for Small Manufacturers

Small manufacturers aren’t limited to one sector. You’ll find them in dozens of industries, often filling gaps big companies ignore.

- Food Processing: Artisanal cheese makers, small-batch hot sauce producers, organic granola brands.

- Furniture Manufacturing: Woodworkers crafting bespoke tables, chairs, or shelving units from reclaimed timber.

- Textile Manufacturing: Local dyers, weavers, or seamstresses making limited-run clothing or home goods.

- Electronics Manufacturing: Hobbyist-turned-business owners building custom circuit boards for medical devices or IoT sensors.

- Plastic Manufacturing: Shops using 3D printers or injection molding machines to make prototypes or niche replacement parts.

- Pharmaceutical Manufacturing: Compounding pharmacies creating personalized medications not available through big pharma.

These businesses often serve local markets first. A bakery that makes gluten-free bread for three nearby cafes isn’t just a food producer-it’s a community supplier. That’s the heart of small-scale manufacturing: connection over scale.

How Small Manufacturers Operate Day to Day

Running a small manufacturing business is messy. There’s no HR department to handle payroll. No legal team to review contracts. The owner often welds parts in the morning and files taxes in the afternoon.

Here’s how their routine usually looks:

- Order intake: Customers reach out via Instagram, Etsy, or word of mouth. No sales reps calling.

- Material sourcing: They buy steel, fabric, or ingredients from local suppliers or small distributors to avoid long lead times.

- Production: Machines run in shifts, or one person works alone. Quality control is personal-each item gets checked by hand.

- Packaging and shipping: Boxes are taped by hand. Labels are printed on a desktop printer.

- Customer follow-up: A thank-you note, a discount code for next time, or a quick call to ask if the product worked.

They don’t use enterprise software like SAP or Oracle. They use spreadsheets, WhatsApp, and free tools like Canva and Square. Their biggest cost isn’t rent or equipment-it’s time. Every minute spent fixing a machine or chasing payment is a minute not spent making product.

Why Small Manufacturers Matter

Big factories make millions of identical items. Small manufacturers make things that matter to real people.

They keep skills alive. In rural Ohio, a family-run machine shop still trains apprentices in manual lathe work-something no university teaches anymore. In Detroit, a small electronics maker repairs vintage radios for collectors, keeping obsolete tech functional.

They’re resilient. During the pandemic, small manufacturers pivoted fast. A brewery in Portland started making hand sanitizer. A sewing studio in Chicago switched from wedding gowns to face masks. They didn’t wait for government aid-they just started making what was needed.

They also reduce waste. Unlike big brands that overproduce to hit shelf quotas, small manufacturers make only what’s ordered. A custom furniture maker doesn’t stock 50 identical chairs. They build one at a time, using only the wood the customer chose.

Challenges Small Manufacturers Face

It’s not easy. Even passionate makers struggle with the same problems:

- Cash flow: Customers pay slowly. Suppliers demand upfront payment. Many go months without profit.

- Access to capital: Banks rarely lend to small manufacturers without years of financial history.

- Regulations: Food safety permits, EPA rules for chemicals, or OSHA standards can be overwhelming without a compliance team.

- Competition from big brands: Amazon sells cheap, mass-produced versions of handmade goods. Customers don’t always know the difference.

- Finding skilled labor: Young people aren’t learning trades like welding, machining, or embroidery. The next generation of makers is shrinking.

Many small manufacturers survive by doing more than just making things. They teach workshops, sell kits, offer repair services, or license their designs. One ceramicist in Nashville started selling clay-making kits online. That side business now brings in more than her original pottery line.

How to Spot a Real Small Manufacturer

Not every Etsy shop is a manufacturer. Some just resell imported goods. Here’s how to tell the difference:

- They show their workspace: Photos of tools, messy workbenches, or hands at work. Not just polished product shots.

- They name their materials: "Made with 100% organic cotton from North Carolina" or "Steel sourced from a local scrap yard."

- They respond personally: Replies to messages come from the owner, not a bot.

- They have a story: "I started this after my dad passed away and I wanted to keep his woodworking bench alive."

- They limit quantity: "Only 15 made this month" or "Custom orders only-no wholesale."

If a company claims to be small but sells 10,000 units a month, they’re probably not. True small manufacturers live by limits. They choose quality over quantity every time.

Where to Find Small Manufacturers

You don’t need to search far. They’re often hiding in plain sight.

- Check local craft fairs or farmers markets.

- Search "made in [your city]" on Instagram or Facebook.

- Look at Etsy filters-sort by "Seller Location" and pick your region.

- Visit your city’s chamber of commerce website-they often list local makers.

- Ask at independent hardware stores, fabric shops, or tool suppliers. They know who’s buying.

Supporting a small manufacturer isn’t just about buying something. It’s about keeping a skill alive, helping a family stay in business, and reducing the environmental cost of global shipping. When you buy from them, you’re not just a customer-you’re part of their story.

Is a small manufacturer the same as a cottage industry?

They’re very similar, but not always the same. A cottage industry usually means production happens in someone’s home, often with minimal equipment-like knitting sweaters or baking cookies. A small manufacturer might operate out of a rented workshop with industrial tools. Both are small-scale, but manufacturers tend to have more formal processes, even if they’re simple.

Can a small manufacturer grow into a big company?

Yes, but many choose not to. Some small manufacturers deliberately stay small because they value control, flexibility, and personal relationships over growth. Others scale up by hiring more staff, opening a second location, or partnering with distributors. But once they hit 100+ employees, they’re no longer considered small manufacturers under most definitions. Growth changes the culture-and not everyone wants that.

Do small manufacturers use automation?

Some do, but not like big factories. A small metal shop might use a CNC machine to cut parts faster, but still hand-finish each piece. A bakery might use a semi-automatic dough divider but still shape each loaf by hand. Automation helps them stay competitive, but they avoid full automation because it removes the human touch that customers pay for.

Are small manufacturers more sustainable than big ones?

Often, yes. They use less energy because they make smaller batches. They source materials locally, cutting down on shipping emissions. They produce only what’s ordered, reducing waste. And they repair, reuse, or recycle materials more often because they can’t afford to throw things away. Big manufacturers optimize for speed and cost. Small ones optimize for longevity and care.

How do small manufacturers compete with Amazon?

They don’t try to beat Amazon on price or speed. They compete on uniqueness, story, and service. A customer might pay $45 for a hand-thrown mug instead of $12 for a mass-produced one because they know the maker’s name, saw the video of how it was made, and trust it won’t chip after a month. Small manufacturers sell meaning, not just products.