When you see a Honda Activa, a CB300R, or a City sedan on Indian roads, you might assume the engine under the hood was made in Japan. But that’s not the full story. Honda engines in India aren’t imported-they’re built right here, by Honda itself, in one of the most advanced manufacturing plants in the country.

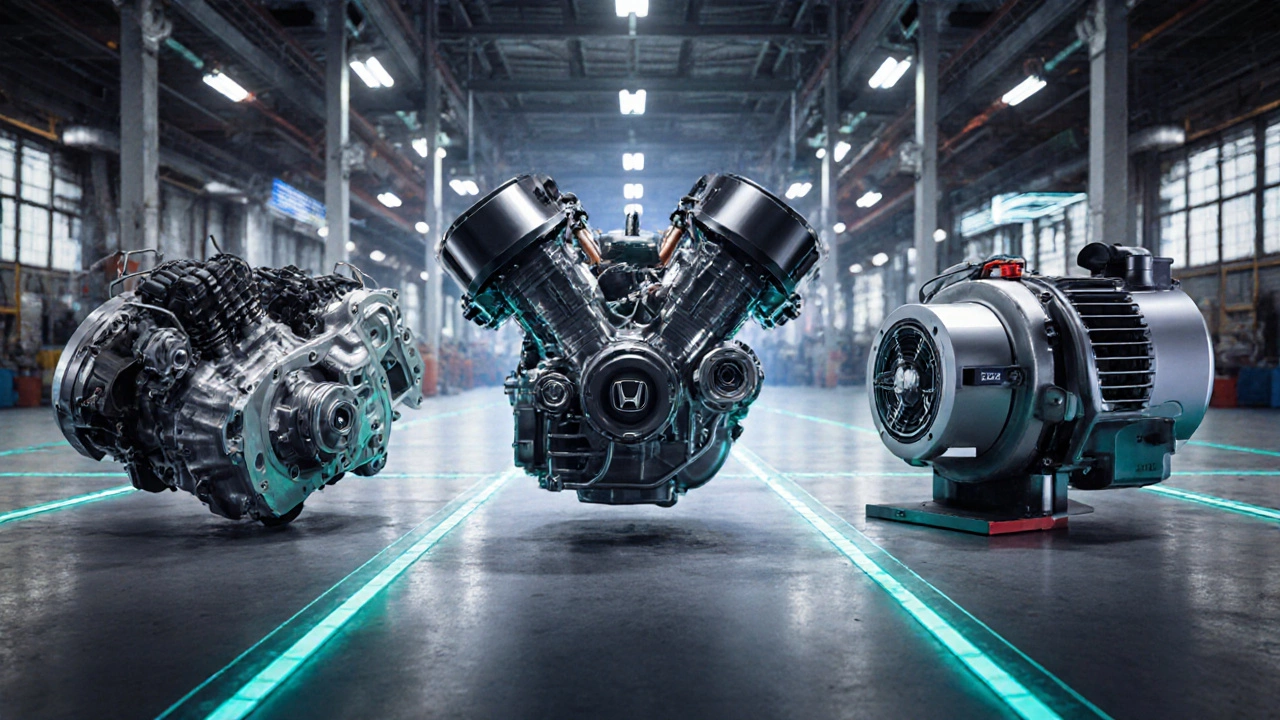

Honda India Manufacturing: A Local Powerhouse

Honda Motorcycle & Scooter India (HMSI) and Honda Cars India Ltd. (HCIL) are the two main companies responsible for making Honda engines in India. Both are fully owned subsidiaries of Honda Motor Co., Ltd. in Japan, but they operate independently on the ground. They don’t just assemble cars and bikes-they design, engineer, and produce every engine used in Honda vehicles sold in India.

The primary engine manufacturing facility is located in Greater Noida, Uttar Pradesh. This plant spans over 200 acres and houses multiple production lines for both two-wheelers and four-wheelers. It’s not a simple assembly line. This is a full-cycle manufacturing hub where raw aluminum and steel are transformed into finished engines with precision tolerances of less than 0.01 millimeters.

Every engine-whether it’s the 110cc air-cooled unit in the Splendor Plus or the 1.5L i-VTEC turbo in the City-goes through the same rigorous process: casting, machining, assembly, and testing. The plant produces over 4 million engines annually, with more than 80% used in vehicles sold domestically. The rest are exported to markets in Southeast Asia, Africa, and Latin America.

Why Make Engines Locally? The Business Logic

Honda didn’t just set up shop in India to save on labor costs. The decision to manufacture engines locally was driven by strategy, not just economics. India’s growing middle class, rising demand for fuel-efficient vehicles, and strict emission norms like BS6 meant Honda needed to adapt fast.

Building engines locally cuts lead times by weeks. Instead of waiting for parts to ship from Japan, engineers in India can tweak designs within days. For example, when BS6 norms came into effect in 2020, Honda’s Noida plant redesigned fuel injection systems and added new sensors to meet the standards-all without delaying production.

Local manufacturing also reduces import duties. Importing a fully built engine into India attracts a 30% customs duty. But when you make the engine here, you only pay a 28% GST on the final vehicle. That’s a massive cost advantage, especially when selling volume-driven models like the Activa.

Technology and Innovation: Made in India, Engineered Globally

Don’t think that “made in India” means lower quality. Honda’s Indian engine plants use the same global standards as Japan. The Noida facility has robotic welding arms, automated leak testers, and AI-driven quality control systems that scan every engine for defects before it leaves the line.

The 125cc eSP+ engine used in the Activa 6G was developed by Honda’s R&D team in India. It features a quiet start system, reduced friction, and better fuel economy than its predecessor. This engine is now exported to over 15 countries, proving that innovation doesn’t always flow from Japan to India-it can go the other way too.

Even Honda’s car engines, like the 1.2L and 1.5L i-VTEC units in the Amaze and City, are tuned for Indian conditions. Higher ambient temperatures, poor fuel quality, and stop-start traffic were all factored into the design. The result? Engines that last longer and need fewer repairs than competitors.

Who Else Is Involved? Suppliers and Partners

While Honda makes the engines, it doesn’t make every single part. Like any major automaker, it relies on a network of suppliers. Companies like Bharat Forge, Minda Corporation, and Denso India supply critical components like pistons, valves, fuel injectors, and sensors.

But here’s the key: Honda owns the design, controls the process, and does final assembly. Suppliers deliver parts to Honda’s plant, where they’re integrated into complete engines under Honda’s strict quality protocols. There’s no outsourcing of engine core manufacturing. No licensing. No joint ventures. Honda keeps full control.

This is different from brands like Suzuki, which partners with Maruti for engine production, or Yamaha, which has a joint venture with Hero MotoCorp. Honda’s approach is vertical integration-everything from the crankshaft to the exhaust manifold is tracked and tested by Honda engineers.

What About the Future? Electric and Hybrid Engines

Honda is preparing for the next wave. While most of its current engines are internal combustion, the company has already started testing hybrid systems in India. The Honda e:NP1, launched in 2024, uses a hybrid powertrain developed in Japan but assembled locally in Noida.

Honda’s Indian R&D center is now working on compact electric motors and battery packs for future two-wheelers. By 2027, the company plans to launch three electric models in India, all with engines (or rather, motors) built in the same Noida facility.

That means the same plant that made the 125cc engine for your Splendor will soon make the electric motor for your next Honda scooter. The infrastructure, workforce, and quality systems are already in place. It’s not a shift-it’s an evolution.

Myths About Honda Engines in India

There’s a common myth that Honda engines in India are “downgraded” versions of Japanese ones. That’s not true. The engine in your Activa 70 is the same basic design as the one sold in Thailand or Vietnam. The only differences are in tuning-adjusted for local fuel quality and traffic patterns.

Another myth is that Honda outsources engine production to local firms like Bajaj or TVS. That’s false. Bajaj makes its own engines. TVS makes its own. Honda doesn’t partner with them for engine manufacturing. Every Honda engine in India is stamped with a Honda serial number and traced back to the Noida plant.

Some people think Honda engines are made in Malaysia or Thailand and shipped to India. That’s also incorrect. While Honda does have plants in those countries, they serve their own regional markets. India’s engine supply chain is completely self-contained.

How to Tell if Your Honda Engine Is Made in India

If you’re curious, you can check your engine’s origin. Look for the engine number stamped on the side of the engine block. It starts with “E” for two-wheelers or “F” for cars, followed by numbers. If the engine number has “IND” or “N” as a code, it was made in India.

For cars, check the vehicle’s certificate of origin or the sticker inside the driver’s door. It will say “Manufactured by Honda Cars India Ltd., Greater Noida.” For bikes, the owner’s manual always lists the engine manufacturing location.

There’s no ambiguity. If you bought a new Honda in India, the engine under the hood was made here.

Why This Matters to Indian Buyers

Knowing that Honda engines are made in India isn’t just trivia-it affects your wallet and your experience. Local production means faster service. Spare parts are more readily available. Repairs are cheaper because the supply chain is short.

It also means better support. When you take your Honda to a service center, the technicians are trained on the exact engines you have. They don’t guess-they know. The same diagnostic tools, the same torque specs, the same software updates-all developed and tested in India.

And if you care about the economy, Honda’s Indian engine plant employs over 8,000 people directly and supports more than 50,000 jobs in the supply chain. That’s not just manufacturing-it’s livelihoods.

Are Honda engines in India made by a local company?

No. Honda engines in India are made by Honda’s own subsidiaries: Honda Motorcycle & Scooter India (HMSI) and Honda Cars India Ltd. (HCIL). These are fully owned by Honda Motor Co., Japan, and operate under Honda’s global standards. No third-party company manufactures Honda engines in India.

Where are Honda engines manufactured in India?

All Honda engines for the Indian market are manufactured at the company’s integrated plant in Greater Noida, Uttar Pradesh. This facility handles everything from casting and machining to final assembly and testing. It’s one of Honda’s largest engine production centers globally.

Are Honda engines in India the same as those made in Japan?

The core design and technology are identical. However, engines sold in India are tuned for local conditions-like higher temperatures, lower fuel quality, and heavy traffic. This tuning improves durability and fuel efficiency under Indian driving conditions. The engine block, valves, and internal components are the same, but software and calibration differ slightly.

Can I trust the quality of Honda engines made in India?

Absolutely. Honda’s Indian plants follow the same global quality standards as Japan. Every engine undergoes 100% leak testing, vibration analysis, and performance checks. The Noida plant has won multiple Honda Group Quality Awards for defect-free production. Many Indian owners report over 150,000 km without major engine issues.

Do Honda engines in India use imported parts?

Some components like high-precision sensors or electronic control units may be imported, but the core engine parts-crankshaft, pistons, cylinder block, valves-are all made locally. Honda owns the tooling and ensures every supplier meets its global specs. The final assembly and quality control are 100% handled by Honda.

Will Honda make electric engines in India too?

Yes. Honda has already started assembling hybrid powertrains in India and is developing electric motors locally. The same Noida plant that builds internal combustion engines will soon produce electric motors for future models. By 2027, Honda plans to launch three fully electric two-wheelers made entirely in India.