- Why Restaurants Rely on Food Processors for Efficiency Dec 24, 2024

- Importing a Car to India from the USA: What You Need to Know Dec 9, 2024

- What Are the 7 Factors of Manufacturing? A Practical Guide for Small Businesses and Government Scheme Applicants Dec 26, 2025

- Plastic Exporter Number One: Who Tops the Global List? May 29, 2025

- Best State to Build a Factory: Manufacturing Success by Location May 14, 2025

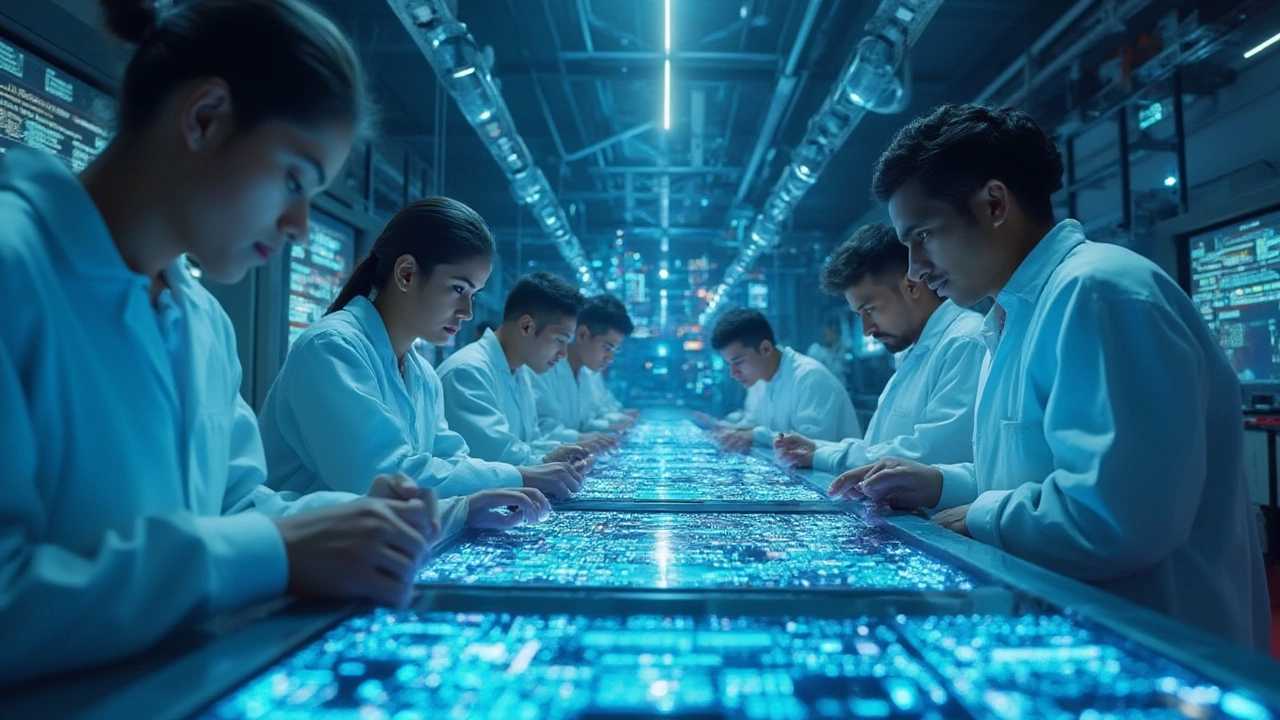

Semiconductor Manufacturing: What You Need to Know

Ever wondered why every new phone, car, or solar panel seems to need more chips? That’s semiconductor manufacturing at work. It’s the process that turns raw silicon into the tiny brains inside every electronic device. In the last few years, demand has surged, and factories are racing to keep up. If you’re curious about how this industry works, what’s changing, and where the biggest chances lie, you’re in the right spot.

Key Trends Shaping the Industry

First off, size matters. Advanced nodes—think 5 nm and below—are now the standard for high‑performance chips. Those tiny features mean faster, more efficient devices, but they also need ultra‑clean rooms and expensive equipment. Next, geography is shifting. While Taiwan and South Korea still lead, India is stepping up with new fabs, tax incentives, and a growing talent pool. This move helps reduce the supply‑chain risk that hit many companies during recent disruptions.

Another trend is the rise of specialty chips. Instead of one giant processor for everything, manufacturers are building processors for AI, automotive safety, and internet‑of‑things (IoT) devices. Those chips are often made with different materials like gallium nitride, which can handle higher voltages. The shift to specialized designs gives companies a chance to charge a premium and opens new market niches.

Overcoming Common Hurdles

Now, let’s talk about challenges. The biggest one is cost. Setting up a fab can cost over $10 billion, and each new generation of equipment adds another billion. That’s why many firms partner with governments or share facilities. A practical tip: if you’re a startup looking to enter the space, consider a “fab‑less” model—design the chips but outsource the actual manufacturing to established foundries.

Supply‑chain reliability is another pain point. Raw silicon wafers, rare gases, and ultra‑pure chemicals all have to arrive on schedule. Some companies mitigate this by keeping safety stock or by diversifying suppliers across regions. Finally, talent scarcity can slow projects. Investing in training programs and collaborating with local universities can help bridge the gap, especially in emerging hubs like Bangalore and Hyderabad.

Bottom line: semiconductor manufacturing is a fast‑moving field with huge upside if you understand the tech, the market, and the practical steps to lower risk. Keep an eye on emerging nodes, watch where new fabs are popping up, and think creatively about how to partner or outsource. With the right approach, you can turn the complexity of chip production into a real business advantage.

AI Chip Manufacturing in India: Who Makes Them and What's Next?

- Aarav Sekhar

- Jul 28, 2025

Discover which companies are making AI chips in India, how India is building its semiconductor industry, and what it means for AI-driven innovation.