- Navigating the Path to Small Scale Manufacturing Success Dec 22, 2024

- Most Profitable Small Scale Manufacturing Business Ideas Apr 6, 2025

- Are Tata Cars Sold Internationally? Exploring Global Reach Mar 2, 2025

- Chemicals Manufactured in India: A Deep Dive into the Industry Apr 14, 2025

- Food Processing Unit Classification: Types and Examples Oct 25, 2025

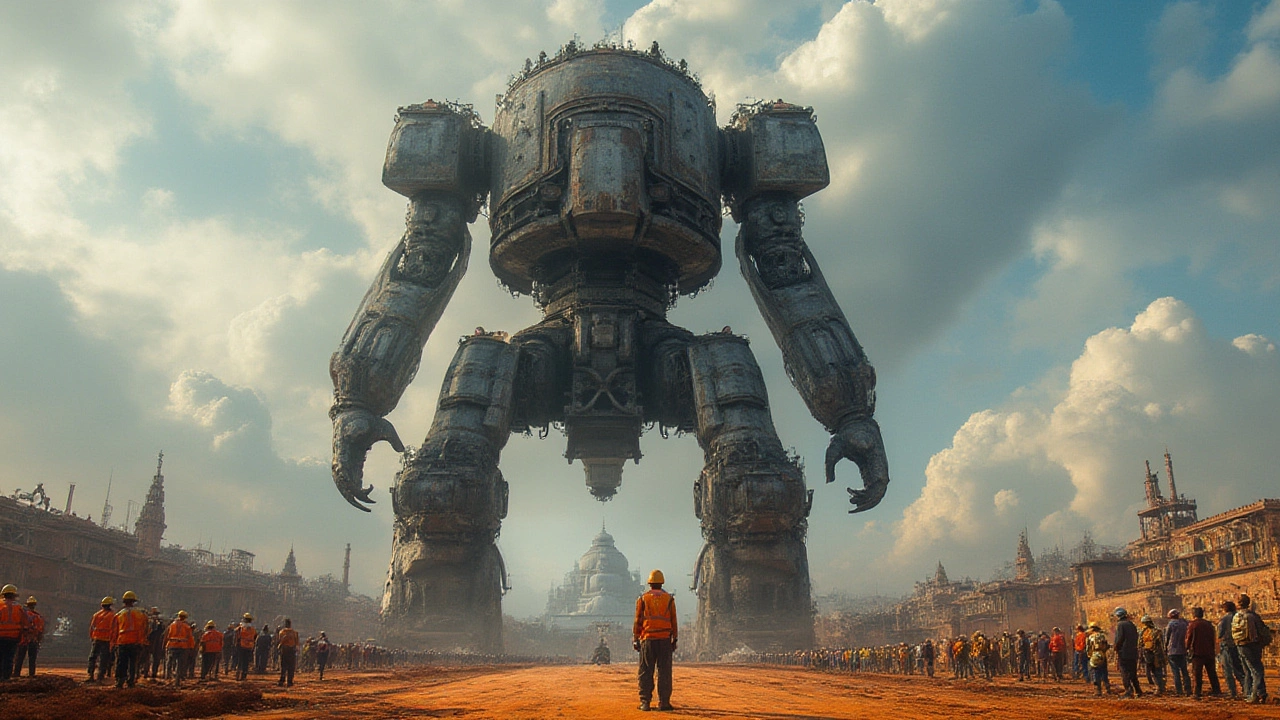

Biggest Machine in India: What It Is and Why It Matters

If you walk into a modern Indian plant and see a piece of equipment that dwarfs everything else, you’ve probably found the country’s biggest machine. It’s not just a bragging right – it’s a tool that reshapes how factories work, speeds up production, and cuts costs. In this guide we’ll show you what makes this machine so big, what it can do, and why it matters to anyone involved in Indian manufacturing.

Why Size Matters in Indian Manufacturing

Big machines bring big advantages. First, they can handle larger raw materials in one go, meaning fewer changeovers and less downtime. Second, they often house advanced automation that smaller units simply can’t afford. That translates into higher output per hour and a tighter schedule for customers. For Indian companies aiming to compete globally, having a giant piece of equipment helps them meet big orders without sacrificing quality.

At the same time, size brings challenges. A massive machine needs a strong floor, proper power supply, and skilled operators. It also requires regular maintenance to avoid costly breakdowns. That’s why many factories partner with specialists like Rise Corp, who provide the expertise to keep the equipment humming.

Key Features of the Country’s Largest Machine

The biggest machine in India is a high‑precision CNC milling center located at a Rise Corp‑backed plant in Gujarat. Here are the standout specs:

- Travel range: 2,500 mm x 1,800 mm x 1,200 mm – enough to machine full‑size automotive frames in one pass.

- Power: 250 kW spindle motor, delivering the torque needed for thick steel and aluminum.

- Automation: Integrated robotic arm for loading/unloading, reducing manual handling by 80%.

- Control system: Latest Fanuc controller with real‑time monitoring and cloud‑based analytics.

- Energy efficiency: Regenerative braking and smart cooling cut electricity use by 30% compared to older models.

What does all that mean for a factory? Imagine cutting a 10‑meter steel beam to exact dimensions in under an hour, with the robot doing the heavy lifting. The result is faster delivery, lower labor costs, and less waste.

Another practical benefit is consistency. The machine’s laser‑guided positioning keeps tolerances within ±0.02 mm, a level of accuracy that even seasoned technicians find hard to match by hand. That reliability builds trust with overseas buyers who demand tight specs.

Of course, you don’t need to own the biggest machine yourself to reap its benefits. Many Indian manufacturers use a pay‑per‑use model, renting time on the equipment when they have big spikes in demand. This approach spreads the cost and lets smaller players compete on large contracts.

In short, the biggest machine in India isn’t just a showpiece – it’s a practical solution that boosts productivity, cuts waste, and opens doors to global markets. Whether you’re a plant manager, an engineer, or a business owner, understanding how this giant works can help you make smarter decisions about capacity, investment, and growth.

Ready to see if your operation could benefit from the power of India’s largest machine? Talk to the experts at Rise Corp. They’ll walk you through the numbers, show you a demo, and help you decide whether buying, leasing, or outsourcing is the right move for your business.

India's Biggest Machine: Discover the Largest Heavy Machinery Ever Built in India

- Aarav Sekhar

- Jul 16, 2025

Explore the story of the biggest machine in India. Packed with surprising facts, this guide reveals its record-breaking size, uses, and the awe-inspiring effort behind its creation.