Small Business Profitability Calculator

Estimate Your Small Business Potential

Calculate how your small manufacturing business compares to large scale operations in profitability, job creation, and sustainability based on industry data from the article.

Your Business Impact

Small vs Large Scale Comparison

Based on article data:

Small Scale Advantages

- Job creation: 2.5x more jobs per $1M revenue

- Startup cost: $5,000–$50,000

- Environmental impact: Low to moderate

- Customization: High (each order unique)

Large Scale Comparison

- Job creation: ~1 job per $1M revenue

- Startup cost: $1M–$100M+

- Environmental impact: Very high

- Customization: Low (standardized products)

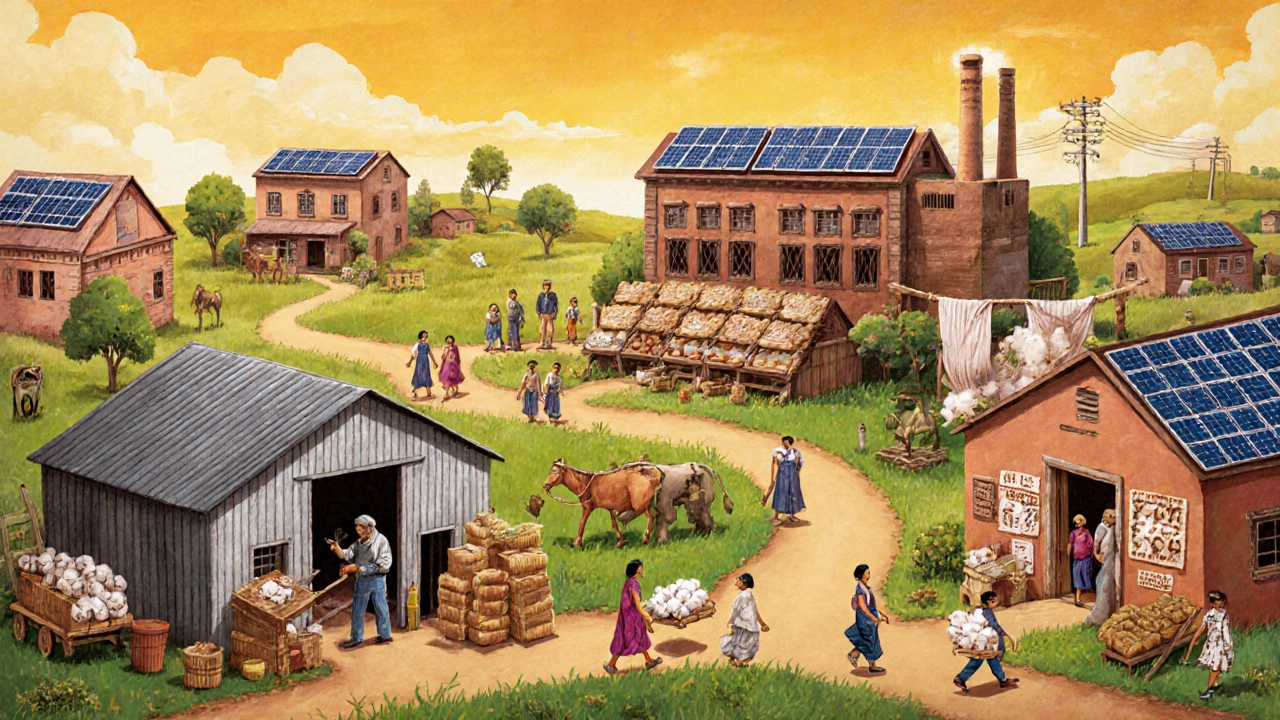

Small scale industries aren’t just tiny versions of big factories. They’re the backbone of local economies, the launchpad for entrepreneurs, and the quiet force behind many of the products you use every day. If you’ve ever bought handmade soap, a locally woven rug, or a custom metal part made just down the road, you’ve benefited from small scale manufacturing. These businesses don’t need billion-dollar factories or global supply chains. They work with limited space, fewer workers, and often just a few machines. But that doesn’t make them weak-it makes them smart, flexible, and surprisingly powerful.

Lower Startup Costs

Starting a big factory can cost millions. You need land, heavy machinery, permits, and a team of engineers. Small scale industries? You can start with under $10,000. A single CNC machine, a few tables, some raw materials, and a small workshop are enough. Many begin in garages, rented sheds, or even home-based setups. This low barrier means more people can try. A tailor in Rajasthan, a ceramic artist in Oaxaca, or a metal fabricator in Ohio can turn a skill into a business without taking on massive debt. That’s why over 80% of manufacturing businesses in developing countries are small scale-they’re the only option most people have.

Quick Adaptation to Market Changes

Big companies take months to change a product design. Small scale industries can do it in days. If a local customer asks for a different color, size, or material, the owner can tweak the process right away. No board meetings. No approval chains. Just a conversation and a quick adjustment. This flexibility lets them respond to trends faster than giants. In 2024, a small batch of custom vegan leather bags sold out in two weeks because the maker switched from synthetic to plant-based dyes after customer feedback. That kind of speed is impossible for a multinational brand tied to long production cycles.

Stronger Local Job Creation

One small factory doesn’t employ 500 people. But 50 small factories? That’s 2,500 jobs. And those jobs stay local. Workers don’t need to move cities. They walk to work. They send their kids to local schools. They spend their paychecks at nearby shops. Small scale industries create employment that’s rooted in the community. In rural India, a single metal tool workshop employs three families-father, son, cousin, and a neighbor. That’s not just a job. It’s a lifeline. Studies show that for every $1 million in revenue, small manufacturers create nearly 2.5 times more jobs than large ones. They don’t just make products-they build neighborhoods.

Less Environmental Impact

Large factories burn tons of fuel, pump out emissions, and generate massive waste. Small scale operations? They use what they need. A woodworker cuts only the pieces required for an order. A food processor makes small batches to avoid spoilage. A textile unit recycles fabric scraps into stuffing or insulation. Many small manufacturers use renewable energy, buy local materials, and avoid plastic packaging. In 2023, a small battery recycler in Michigan recovered 98% of materials from old power tools-no landfill needed. Their scale isn’t a weakness. It’s a built-in sustainability feature.

Customization and Niche Markets

Big brands sell the same thing to millions. Small scale industries sell the right thing to the right person. A bakery makes gluten-free sourdough for one town. A toolmaker builds custom wrenches for vintage car restorers. A furniture shop crafts tables with built-in charging ports for remote workers. These aren’t mass-market products. They’re solutions for specific needs. That’s why small manufacturers often charge more-and customers pay. People don’t want generic. They want personal. Small scale industries thrive by filling gaps big companies ignore.

Resilience During Crises

When global supply chains broke down in 2020, big manufacturers stalled. Small ones kept going. Why? They didn’t rely on parts shipped from halfway across the world. They used local suppliers. When diesel prices spiked, they switched to electric tools. When workers got sick, they hired neighbors. In 2022, a small electronics repair shop in Brazil kept running during a national power outage by using solar-charged batteries. Their size made them agile, not fragile. Big companies plan for worst-case scenarios. Small ones live them-and adapt daily.

Direct Customer Relationships

At a big company, you’re a number. At a small workshop, you’re a person. Owners know their customers by name. They remember preferences. They answer calls directly. This trust builds loyalty. A customer who buys a handmade knife from a blacksmith in Tennessee doesn’t just buy a tool. They buy a story. They get updates on the maker’s new designs. They’re invited to open houses. That connection turns one-time buyers into lifelong supporters. No ad campaign can replicate that.

Access to Government Support

Many governments actively encourage small scale industries because they know their value. In India, the MSME scheme offers subsidized loans, tax breaks, and training. In Germany, small manufacturers get grants for automation upgrades. In the U.S., the SBA provides low-interest loans and free business counseling. These programs don’t exist for Fortune 500 companies-they’re designed for the little guys. That support helps small businesses survive, grow, and innovate without needing venture capital.

Lower Operational Complexity

Big companies need HR departments, legal teams, compliance officers, and IT networks. Small scale industries? One person often handles sales, production, accounting, and customer service. That sounds overwhelming-but it’s simpler. There’s no bureaucracy. No internal politics. No layers of managers slowing things down. Decisions happen fast. Mistakes are fixed quickly. Resources aren’t wasted on paperwork. This simplicity means less stress and more focus on what matters: making a good product and serving real people.

They Fuel Innovation

Most breakthroughs in manufacturing start small. The first 3D printer was built in a garage. The first electric bike company started with two people and a bike frame. Small scale industries test ideas that big companies won’t risk. They experiment with new materials, processes, and designs. When those ideas work, big players copy them. But by then, the small maker has already moved on to the next thing. Innovation doesn’t need a corporate lab. It just needs a curious mind and a workbench.

| Feature | Small Scale Manufacturing | Large Scale Manufacturing |

|---|---|---|

| Startup Cost | $5,000-$50,000 | $1M-$100M+ |

| Production Speed | Days to weeks | Months to years |

| Customization | High-each order can be unique | Low-standardized products only |

| Job Creation per $1M Revenue | ~2.5 jobs | ~1 job |

| Supply Chain Reliance | Local or regional | Global, complex |

| Environmental Footprint | Low to moderate | Very high |

Who Benefits the Most?

Small scale industries don’t just help the owners. They help everyone around them. Farmers sell raw cotton to a local textile mill. Mechanics buy custom tools from a nearby fabricator. Students get internships at neighborhood workshops. Local governments get more tax revenue from small businesses than from empty warehouses. Communities with strong small manufacturing sectors have lower unemployment, higher home ownership, and stronger schools. They’re not just economic units-they’re social anchors.

Why This Matters Now

In 2025, supply chain fragility, inflation, and consumer demand for authenticity are pushing people back to local production. People want to know where their stuff comes from. They want to support neighbors. They want products made with care, not just speed. Small scale industries are answering that call. They’re not going to replace Amazon or Tesla. But they’re becoming the preferred choice for quality, ethics, and community. That’s not a trend. It’s a return to something older-and better.

Are small scale industries profitable?

Yes, many are. Profitability depends on margins, not volume. A small bakery making 50 loaves a day at $8 each with $3 cost per loaf earns $250 daily. That’s $7,500 a month. After rent, utilities, and supplies, net profit of $3,000-$5,000 is common. Unlike big manufacturers, small ones don’t need to hit billion-dollar sales to survive. They thrive on steady, loyal customers and low overhead.

Do small scale industries use modern technology?

Absolutely. Many use affordable CNC machines, 3D printers, digital design software, and online sales platforms. A small metal shop today might use a $15,000 laser cutter and sell via Etsy or Shopify. Technology isn’t the problem-it’s access. But tools are cheaper than ever, and training is often free through local chambers of commerce or government programs.

Can small scale industries compete with big brands?

They don’t compete on price or scale. They compete on quality, speed, and personal connection. A big brand sells 10,000 identical mugs. A small maker sells 200 custom mugs with your name, your dog’s face, and a quote you wrote. Who wins? The customer who wants something unique. Small industries win by being different, not bigger.

What are the biggest challenges for small scale industries?

Access to capital, finding skilled labor, and competing with cheap imports. Many struggle to get bank loans because they lack collateral. Some lose customers to imported goods that look similar but cost half as much. But these challenges are surmountable. Community support, government grants, and digital marketing can help small makers overcome these hurdles.

How can someone start a small scale manufacturing business?

Start with one skill and one product. Make it, sell it to five people, get feedback, improve. Use free tools like Canva for labels, Instagram for marketing, and PayPal for payments. Apply for local small business grants. Join a maker space to share tools. Don’t try to build a factory on day one. Build a reputation first. Many successful small manufacturers started with just a table, a drill, and a dream.

Final Thought: It’s Not About Size-It’s About Impact

A small scale industry doesn’t need to be big to matter. It just needs to be real. Real people. Real work. Real impact. The world doesn’t need more faceless factories. It needs more makers who care. More hands that shape things with pride. More businesses that lift up their towns. That’s the real advantage of small scale manufacturing-not the numbers, but the humanity behind them.